PP-H AlphaPlus® Sheets

Order no. 010027024

Homopolymer, alpha-nucleated, permanent-heat stability, grey

Product properties

- Permanent-heat stability

- High chemical resistance

- Excellent for use in chemical tank and equipment construction

- Alpha-nucleated

- Good long-term properties when exposed to a range of media

- High rigidity in upper temperature range

Approvals/certifications

- Drinking water certification as per KTW and DVGW W270

- DIN 4102 B2 normal flammability (self-assessment without test certificate)

- Physiological safety in accordance with BfR

- Food compliance EU 10/2011

- Food compliance FDA

Processing

PP-H AlphaPlus Data sheet

Homopolymer, alpha-nucleated, permanent-heat stability, grey

CaseStudy 55 - Lining the interior of food silos with SIMONA® PP-H AlphaPlus® Brochures

TATE & LYLE plc is an international British company in the food industry and it specialises in the production of sweeteners, starch and food supplements. The company's Dutch subsidiary commissioned Roos & Co. Kunststoff- und Metallverarbeitungs GmbH to rehabilitate food silos. The interiors of the six concrete silos were lined with SIMONA® PP-H AlphaPlus® sheets, which proved to be a convincing solution on account of their food compliance, easy processing capability and high chemical resistance.

PDF | 3.67 MB

CaseStudy 56 - SIMONA® PE 100 pipes, fittings and PP-H AlphaPlus® sheets for Europa-Park in Rust Brochures

|

CaseStudy 57 - SIMONA® PFA protects reactor cover against wear and corrosion Brochures

OOO “Perm Chemical Company”, a Russian chemical manufacturer, commissioned OOO “Novitek” to make a reactor cover for a steel reactor. A protective layer made of SIMONA® PFA-GK inside the new cover ensures that the latter withstands the demanding operating conditions of the chemical reactor. The excellent chemical and high temperature resistance of SIMONA® PFA-GK sheets rolong the service life of the reactor and at the same time minimise the need for maintenance work.

|

CaseStudy 43 - SIMONA® PP AlphaPlus®– The lining material for superior safety in plant engineering Brochures

G&H Kunststofftechnik GmbH & Co. KG specialises in the lining of CDC tanks for cathodic dip coating (CDC) of body panels. For the first time in the commercial vehicle sector, an existing steel CDC dipping plant was to be lined with plastic for Claas Selbstfahrende Erntemaschinen GmbH. G&H chose SIMONA® PP AlphaPlus® as a proven lining material for this purpose.

PDF | 701.66 KB

CaseStudy 42 - Lining of a cathodic electrocoating system with SIMONA® PP AlphaPlus® for Adam Opel AG Brochures

G&H Kunststofftechnik GmbH & Co. KG was commissioned by Adam Opel AG to line the interior of an existing standard-steel continuous-flow system for cathodic electrocoating of automotive body parts. For this application plastic was used for the first time at Opel. Due to the high demands made on the lining material in terms of chemical resistance, the contractor opted for SIMONA® PP AlphaPlus® Sheets and Pipes.

PDF | 166.20 KB

CaseStudy 33 - Collection tank for acid solutions – made with SIMONA® PP-DWU AlphaPlus® Brochures

G&H Kunststofftechnik GmbH & Co. KG was commissioned to construct a collection tank for the storage of acid solutions for an aluminium anodising plant. SIMONA® PP-DWU Alpha-Plus® was the material of choice. Boasting a high level of chemical resistance, it is perfect for constructing tanks and installations. The entire tank was assembled on site and then integrated into the instal lation as a whole at its final location.

PDF | 93.63 KB

CaseStudy 19 - SIMONA® P-DWU AlphaPlus® Twin-Wall Sheets: storage tanks for acid solutions Brochures

When it came to designing chemically resistant tanks, Angenstein AG, a Swiss company, opted for an innovative technical solution: SIMONA® PP-DWU AlphaPlus® Twin-Wall Sheets are used by customer DSM Nutritional Products Ltd Branch Pentapharm as media-resistant, FDA-compliant tanks for acid chromatography buffer solutions in the purification of proteins. The SIMONA Technical Service Centre analysed the rectangular tanks with a method of calculation specially developed for Twin-Wall Sheets.

PDF | 298.95 KB

CaseStudy 17 - Pickling line made of SIMONA® PP-DWU AlphaPlus® delivered to Rasselstein GmbH Brochures

The entire process section of the sulphuric acid hot-strip pickling line at Rasselstein GmbH in Andernach, one of the largest tinplate manufacturers in the world, had to be rebuilt. Kunststoffbau Langschede GmbH convinced Rasselstein that SIMONA® PP-DWU AlphaPlus® was the material of choice. As part of the overall design process, the structural parameters as well as the expansion and connections of the various pickling tanks had to be taken into account. An essential prerequisite: top-quality materials. The use of highend measurement technology, including 3D laser scanning, for the purpose of implementing the new process element within existing plant structures provided the basis for efficient assembly within just 20 days.

PDF | 503.30 KB

CaseStudy 11 - SIMONA® PP-DWU AlphaPlus – The Way Forward in Tank and Apparatus Construction Brochures

In February 2007, G&H manufactured a cathodic electrocoating bath with a metal shell for Faurecia, Pisek (Czech Republic). A cathodic electrocoating bath is used to coat parts with paint by an immersion process at room temperature, e.g. automotive components. To prevent potential equalisation between the medium and the steel bath, the latter was equipped with an internal lining of SIMONA® PP-DWU AlphaPlus® using the loose-shirt method.

PDF | 410.46 KB

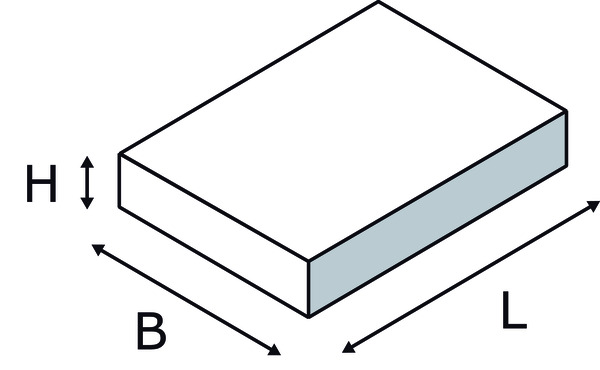

Tolerances Sheets extruded Brochures

Tolerances of SIMONA® extruded Sheets

PDF | 58.12 KB

tech.info - SIMONA® PP Brochures

tech.info SIMONA® PP Semi-Finished Parts. Polypropylene – a material with an asymmetrical chemical structure, as opposed to polyethylene – can be subdivided into groups according to various characteristics.

PDF | 1.44 MB

SIMONA® PP-H AlphaPlus® Added value in chemical tank and equipment engineering Brochures

SIMONA® PP-H AlphaPlus® is a homopolymeric polypropylene (PP-H) featuring a specially modified formula that makes it the perfect choice for applications within the area of industrial tank and plant engineering.

PDF | 816.18 KB

CaseStudy 58 - SIMONA® PE 100 products for a drinking water pipeline in Belgium Brochures

Renovation of the existing drinking water supply network in Sint-Niklaas (Belgium) was a particular challenge for FARYS, a Belgian water supply company. Owing to the existing infrastructure, numerous obstructions had to be bypassed in route planning, as a result of which it was necessary to implement a combination of open-cut and trenchless pipelaying.

|