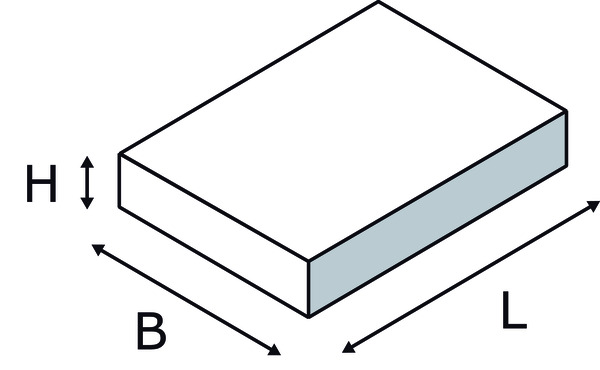

PVDF-SK Sheets

Order no. 030004015

Partially fluorinated high-performance plastic, homopolymeric polyvinylidene fluoride, polyester-backed, UV stability

Product properties

- High-performance material

- Low flammability

- Excellent chemical resistance

- Exceptionally good ageing resistance

- High rigidity

Areas of use

- Chemical installations

- Pharmaceuticals and bioindustry

- Mining

Approvals/certifications

- Produced from raw material with USP class VI certification

- Produced from DIBt-approved moulding compound

- DIN 4102 B1 low flammability (self-assessment without test certificate)

- Physiological safety in accordance with BfR

Processing

PVDF-SK Data sheet

Partially fluorinated high-performance plastic, homopolymeric polyvinylidene fluoride, polyester-backed, UV stability

ProjectReport 16 - Composite tank structures made of SIMONA® PVDF-GK/FRP Brochures

Our client Christen & Laudon in Bitburg-Staffelstein, the leading manufacturer of tanks made of FRP, FRP composite and pure thermoplastic, constructed two storage tanks of FRP composite design (FRP= glass-fibre reinforced plastic) for Bayer AG in 2003. SIMONA® PVDF-GK sheets were used for this project.

PDF | 450.36 KB

CaseStudy 40 - High-purity systems for semi-conductor production – the perfect SIMONA® product for all components Brochures

atp GmbH specialises in end-to-end concepts developed for applications in the semi-conductor industry, including the production of high-purity media distribution and disposal systems, as well as plant and process equipment. Sheets, pipes and fittings from the product groups SIMONA® PP white, SIMONA® PVC-GLAS, SIMONA® PVDF and SIMONA® PP-H AlphaPlus® were used for the production of two wet-processing units and ten chemical supply systems.

PDF | 222.28 KB

CaseStudy 08 - PVDF circular tank withstands high service temperatures Brochures

In 2006, the Hungarian company MULTILATERAL KFT. awarded TÜRK-MŰANYAG BT. a contract to manufacture a polymer-based processing tank for mobile phone batteries – to be operated with 10 % hydrochloric acid at a temperature of 80 °C. Owing to the highly corrosive medium, the relatively high processing temperature and the abrasive properties of the ground material, SIMONA® PVDF was chosen in collaboration with the SIMONA AG Technical Service Centre and UMUNDUM BT. in order to be able to run the process at even higher temperatures if necessary.

PDF | 226.49 KB

CaseStudy 04 - Bayer AG finds cutting-edge solution for large acid tanks Brochures

In 2003, Bayer AG commissioned Christen & Laudon to manufacture two storage tanks based on a GRP composite design (glass-fibre backed plastic) for the storage of hydrochloric acid. The size of the tanks and the special requirements of the application called for high-end materials. Due to the enormous size of the planned tanks, Christen & Laudon only considered a GRP composite construction.

PDF | 107.26 KB

Tolerances Sheets extruded Brochures

Tolerances of SIMONA® extruded Sheets

PDF | 58.12 KB