SIMONA® PE 100 AP Line waste-water pipe systems

The piping system with an abrasion-resistant inner layer

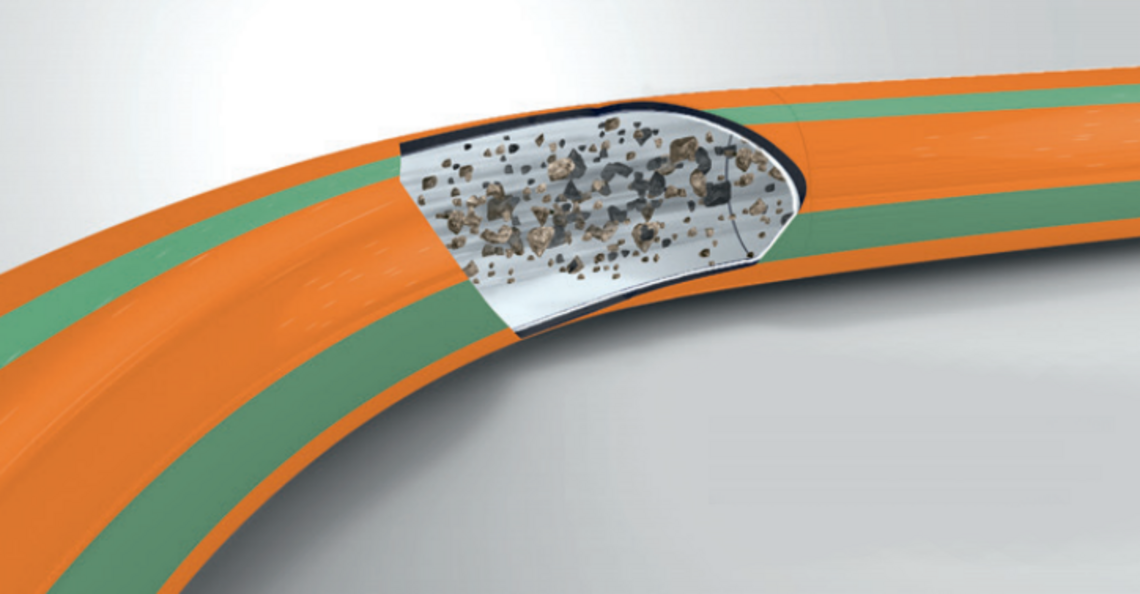

When it comes to wastewater applications, in particular, piping systems are invariably exposed to a continuous, high level of mechanical stress due to sand, fine-grain gravel and a mixture of substances bound in the sewage sludge. For years now, SIMONA has been developing plastic piping system solutions with an increased level of abrasion resistance in order to prolong service life in those cases in which there is exposure to substantial mechanical stress.

SIMONA® PE 100 AP-Line pipes and fittings were also developed specially for applications in the field of wastewater transport where erosion is caused by the constant discharge of solids. In these pipelines the inner surface is highly wear-resistant (AP = Abrasion Protection).

In the past, standard SIMONA® PE 100 pipes have already proved the perfect choice on account of their excellent wear resistance compared to that of conventional materials such as GRP and steel. By comparison, the new SIMONA® PE 100 AP-Line pipes are characterised by yet another significant improvement in abrasion resistance, and hence an increase in service life when in operation.

Where pipes are laid horizontally, the pipe bottoms are the internal surfaces that are subjected to the highest loads. Fittings with deflections, such as bends or branches, are exposed to a particularly high level of abrasion.

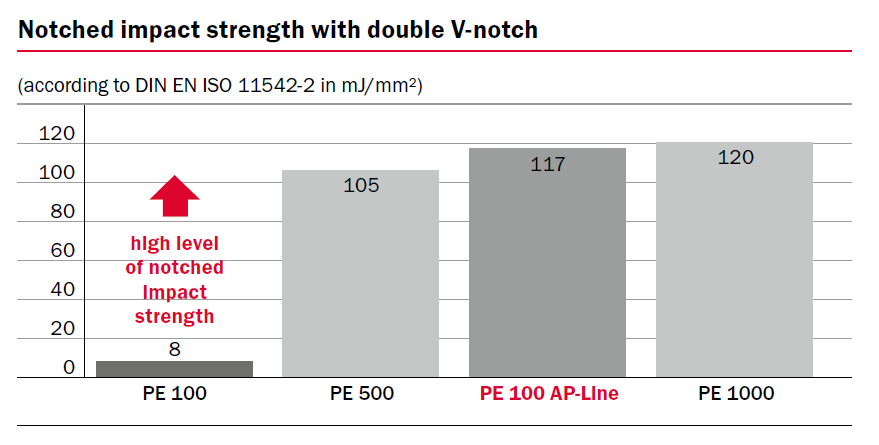

Excellent notched impact strength

In addition to high abrasion resistance, the inner layer also

has a very high level of notched impact strength, combined

with the benefit of being able to absorb a large amount of

impact energy. This provides a distinct advantage for the

hydraulic and pneumatic transport of solids with a high proportion

of sharp-edged particles, such as sand and gravel.

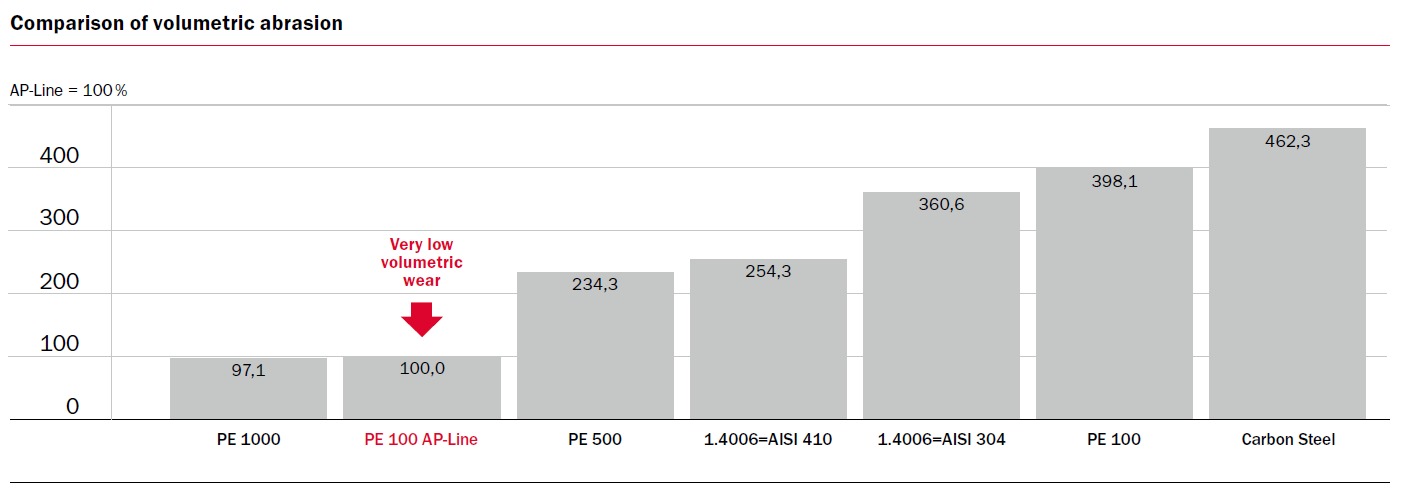

Excellent abrasion resistance

Compared to other common pipe materials, SIMONA® AP-Line exhibits much less volumetric wear in sand-slurry tests due to the high degree of wear protection provided by its integrated inner layer. In fact, wear is 2.5 to 4.6 times less than with various grades of steel. Consequently, the service life expectancy of SIMONA® AP-Line pipes is longer than that of conventional solutions.

The AP-Line piping system also displays tangible benefits when compared with products made of PE 1000 and PE 500. Although the amount of wear is approx. 3 % lower in the case of PE 1000, for example, SIMONA® PE 100 AP-Line piping systems enable efficient processing in accordance with DVS and installation by means of all standard closed and open methods of pipelaying, thus ensuring much lower total costs over the service life.

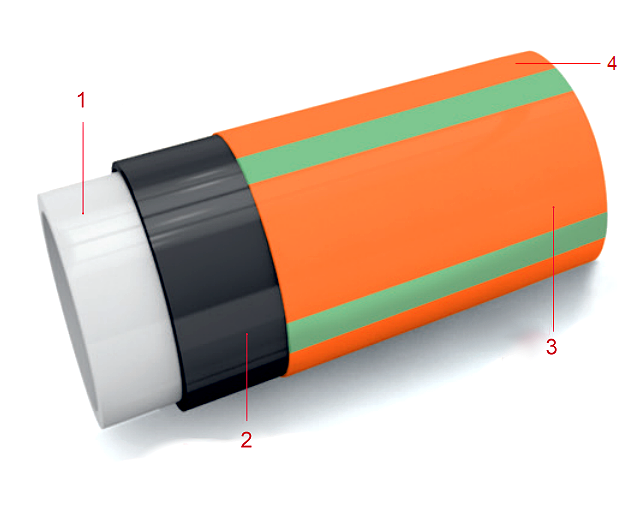

Structure of the tube

(1) Pressure-resistant PE 100 RC inner pipe

Abrasion-resistant, impact-resistant inner layer. Co-extruded pipes and fittings are produced with an integrated inner layer made of a modified polyolefin compound.

(2) Pressure-resistant and welding in accordance with DVS

Pipes and fittings made of PE 100 RC and polyolefin compound that can be welded in accordance with DVS using standard methods.

(3) SIMONA® SPC protective-jacket pipes

The additional outer protective jacket made of modified polypropylene (PAS 1075 Type 3) protects the inner pipe against damage, especially in the case of trenchless methods of laying. Afterwards the inner pipe still has

100 % new-pipe quality.

(4) SIMONA® PE 100 RC

Multilayer pipe made of PE 100 RC (PAS 1075 Type 2) with functional indication layer for all-embracing quality monitoring.

SIMONA® PE 100 AP-Line pipes and fittings – key benefits

- Pipes and fittings with abrasion-resistant, impactresistant inner layer

- Permanently strong, watertight joints made by standard DVS welding methods

- Homogeneous connection of inner layer and inner pipe by means of coextrusion

- Easy and efficient laying and assembly due to the light material weight of the 6 m and 12 m pipes; non-standard lengths are available on request

- High corrosion resistance and chemical resistance

- Much longer service life

- Reduced assembly and maintenance costs

- Application-oriented non-standard components available on request (e.g. customised radius to suit hydraulic conditions)

Additional benefits of SIMONA® PE 100 SPC AP-Line at a glance

- Excellent bond strength and shear strength between inner pipe and

protective jacket (tested on batch-by-batch basis)

- High abrasion resistance of the PP Protect protective jacket

- No crack propagation from the protective jacket into the inner pipe

- High inner pipe resistance to slow crack propagation (PE 100 RC)

- Extremely effective protection against major physical damage such as notches, abrasion and wear (PE 100 SPC)

- Pipelaying can be performed using

Extensive product range

SIMONA’s in-house workshop oversees the production of fittings engineered from SIMONA® PE 100 AP-Line pressure pipes. Pipes and fittings are generally available in outside diameters from 160 mm to 630 mm in classes SDR 17 and SDR 11. Other components and pipes in different SDR series are available on request, e.g. pipes with antistatic treatment, non-standard components and sheets to complement the system.

| SIMONA® PE 100 AP-Line, SDR 11/SDR 171 | |

|---|---|

| Outside diameter d (mm) | |

| Pipes | |

| Pressure pipes2 | 160 – 630 |

| Fittings | |

| AP-Line loose flange (F-piece) | 160 – 630 |

| Tee, reduced | 160 – 630 |

| Bends, welded, 30° to 90° | 160 – 630 |

| Bends, seamless, 11° to 90° | 160 – 400 |

1 Nominal pressure load in relation to effective PE 100 wall thickness.

2 Pipes with added inner layer for full pressure-specific load-bearing capacity available on request.