SIMONA® SEMICON

Highest standards for hightech

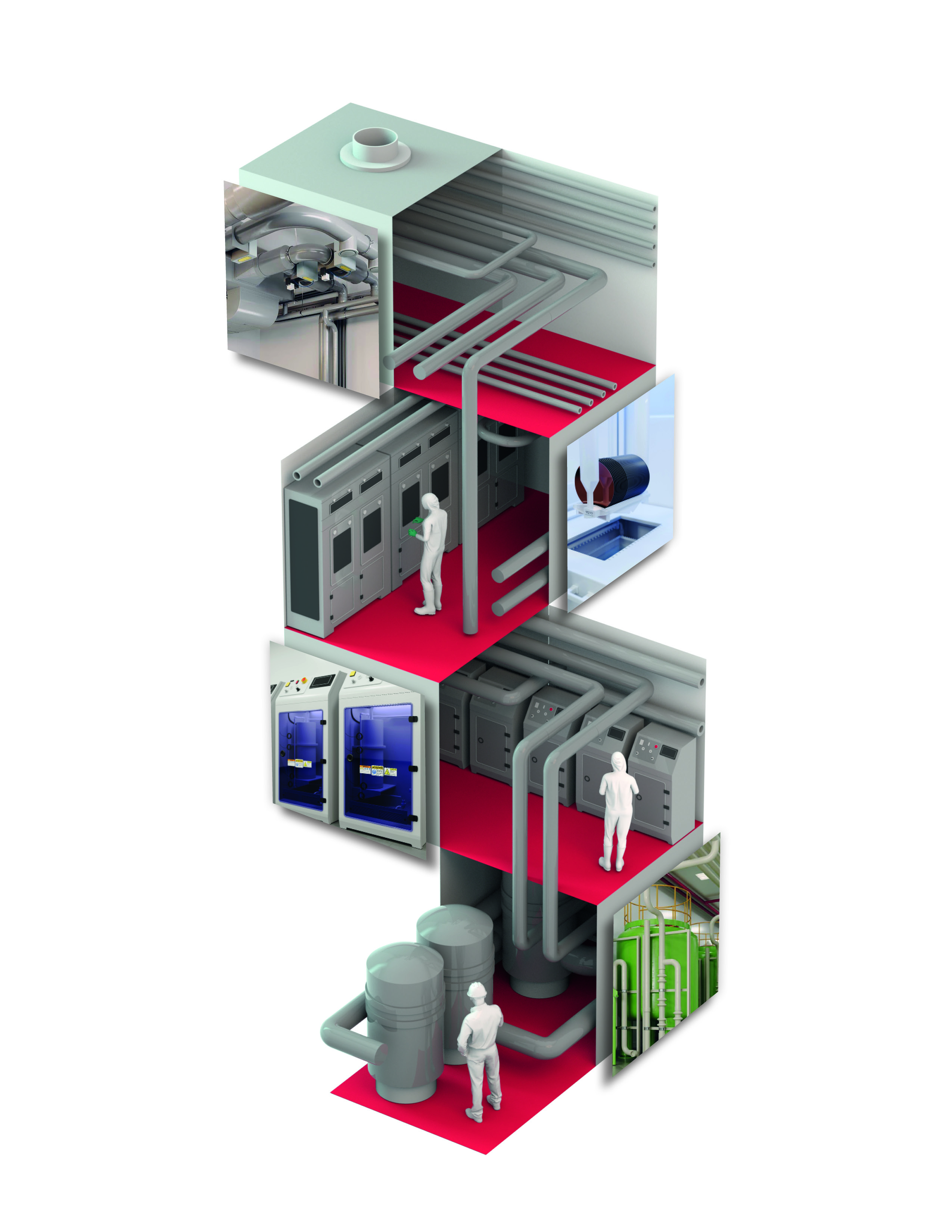

When it comes to the technically and commercially demanding semiconductor industry, it is imperative that all materials deployed meet the highest standards of purity and reliability.

As one of the most comprehensive thermoplastic product portfolio available to semiconductor processors and fabricators, SIMONA® SEMICON has proved effective for all application steps. Among the compelling benefits are exceptional chemical resistance and high impact resistance, combined with features such transparent materials for high visibility.

Thus, all SIMONA® SEMICON products meet the exacting global standards of the semiconductor industry while being produced locally, resulting in perfect, customized solutions at your location, such as FM PVC being produced in three continents. Our teams have a profound knowledge from A to Z which enables us to fully understand your requirements in materials, applications, and logistics.

Produced locally. Certified globally. Tailored to your cleanliness requirements.

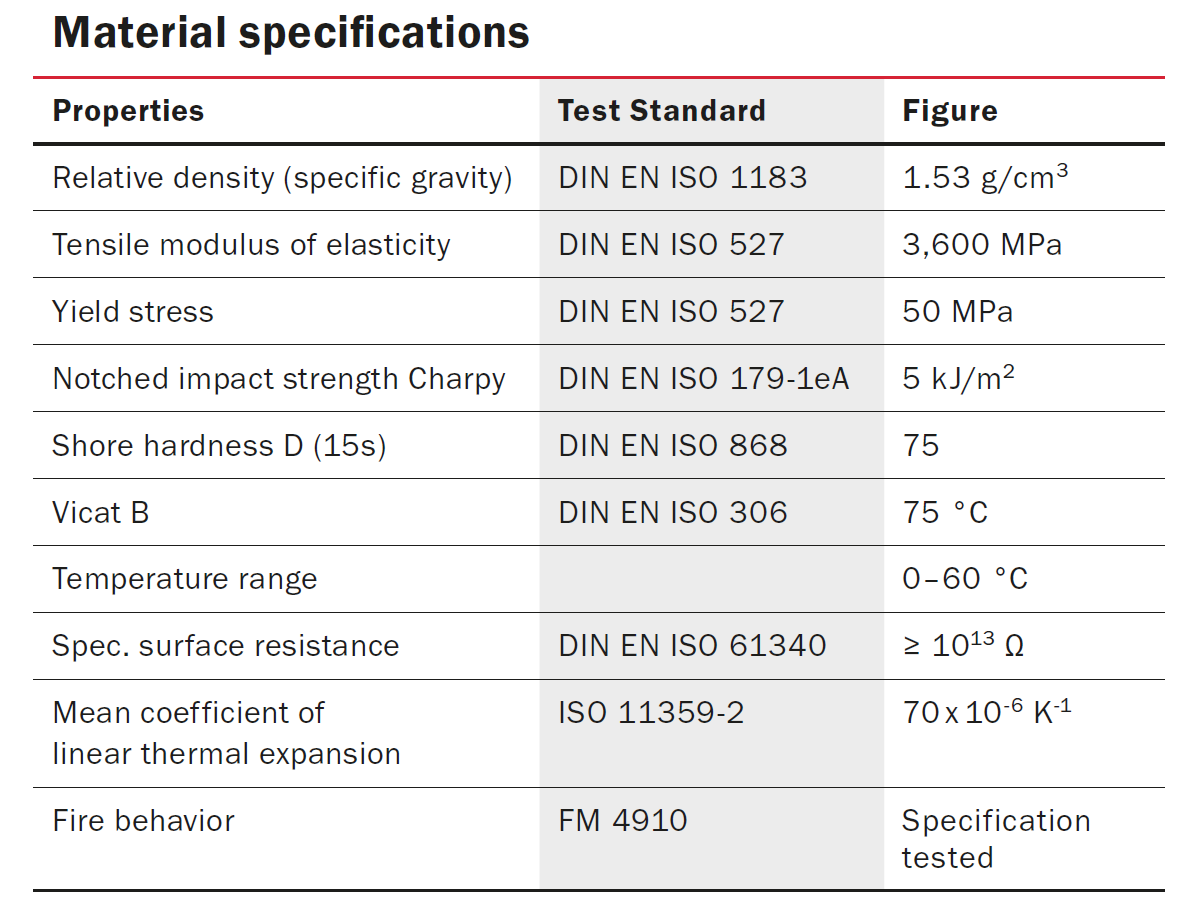

Cleanliness goes hand in hand with safety, particularly when it comes to the fire behavior of materials. It is here that the FM 4910 standard has become a global benchmark: minimum flame spread, limited smoke emission, and maximum safety. Produced locally and certified globally, SIMONA® PVC-U FM 4910 meets the strictest cleanliness standards and will protect your operational processes to the greatest extent possible. Committed to offering the full breadth of our product range worldwide, we have now also commenced production in Germany, thereby complementing our operations in China and the United States.

Key Benefits

Improved safety for your processes and systems

FM 4910-approved: minimal smoke emission and hardly any flame spread – for maximum safety in cleanrooms and reduced risk of production downtime.

- Efficient processing without compromise

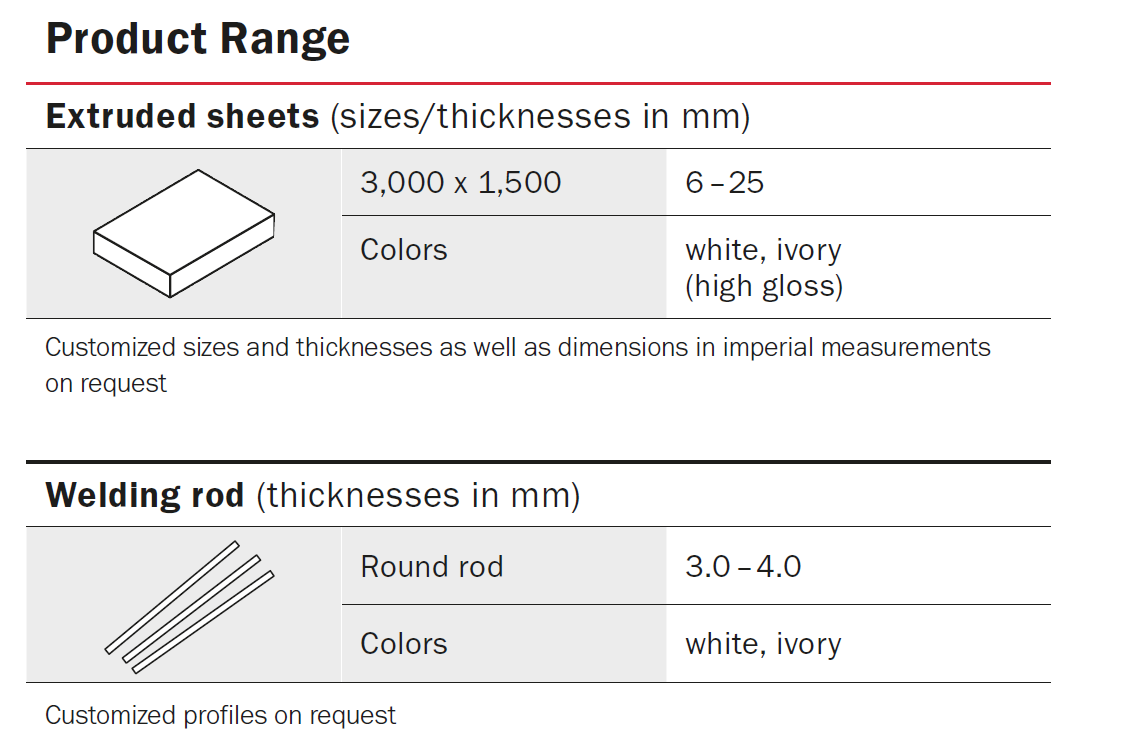

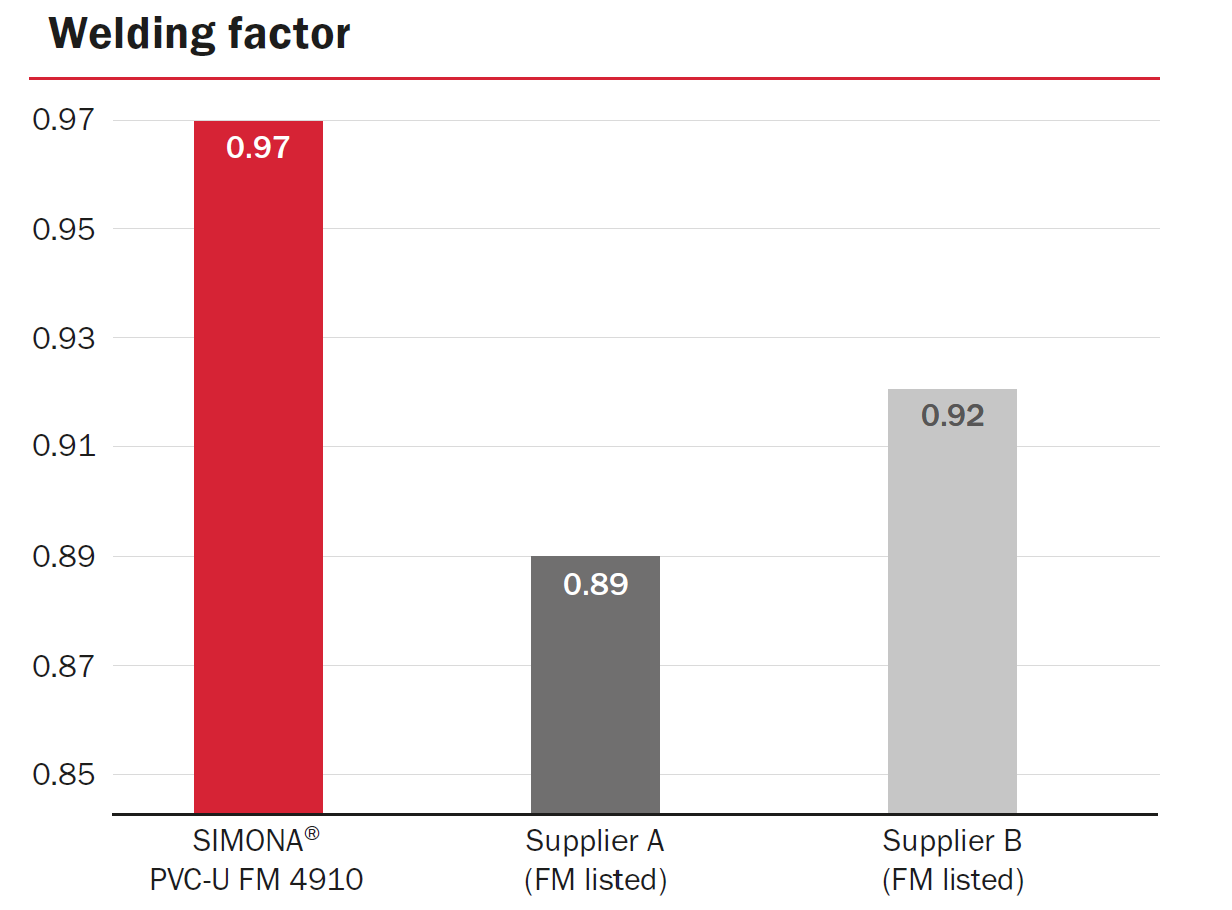

Sheets and welding rods from the same formulation with a welding factor close to 1.0 for a seam strength comparable to that of the base material. This means minimal finishing effort, shorter assembly times, and maximum process reliability.

- Reliability in challenging chemical applications

Highest resistance to strong acids and alkalis as well as outstanding impact resistance and mechanical strength – for a long service life and lower maintenance costs.

- Professional cleanroom design

The white and ivory high-gloss finish creates a clean, modern environment and is also compatible with existing installations.

Applications

- Enclosures for wet-chemical process equipment (e.g., in cleanrooms)

- Chemical distribution systems and valve boxes

- Cleaning modules

- Wafer transfer interfaces

- Switch cabinets

Your benefits at a glance

- Full Service Provider

wide range of sheets, pipes, rods and welding rods designed to satisfy semiconductor process applications without compromise - Maximum safety for your application

due to low-flammability plastics, withstanding temperatures from 140 to 425°F (60 to 218°C) and an excellent chemical resistance - Customized solutions worldwide

meets high global standards such as FM 4910 and UL 94 V-0 flame test criteria

Satisfying Semiconductor process applications without compromise

The right solution for every application in a semiconductor fab

Flexibilty and Support like nowhere else

Our service network goes above and beyond industry standards. For the efficient management of your project, we connect you with various SIMONA services.

- Globalisation

SIMONA® SEMICON offers the most complete product portfolio in the Americas, Europe and Asia. Our products include semi-finished sheets, rods and welding rods, FM 4910 materials including FM-PP, FM-PVC and fluoropolymers and PP and PVDF pipes and fittings. - SIMONA Academy

A highly professional and trusted partner when it comes to imparting specialist knowledge in the field of plastics engineering.

- Technical Service Center

A global consulting service provided by our Technical Service Center and our Customer Service unit. Includes project planning, the selection of products and materials and technical consulting during on-site planning. - SIMCHEM

Online database with details of the chemical resistance with over 4,000 results.

Proven in the planning and construction of high-purity process systems

For this technically and commercially demanding field of application, materials have to meet the highest standards of purity and reliability. Our PVDF range of products for the semiconductor industry meets the highest requirements in terms of purity and offers top-level approval that is important for this sector: FM 4910.

In the manufacture of laboratory components such as installation furniture the white SIMONA® PP Sheets, with their high surface quality, meet the cleanroom conditions that are essential for semiconductors Engineering.

Special properties of SIMONA® PVDF

- High-performance material

Low flammability in accordance with FM 4910

- Excellent chemical resistance to high-purity acids and alkalis

- Exceptional ageing resistance

- High rigidity

- High stress crack resistance and corrosion resistance

- Excellent processing properties

- High surface quality

- Purity requiremen

- UV stability

Your global partner for customzied solutions - worldwide

Based on your specific requirements, we will work with you to design a tailored thermoplastic solution for every application step in the semiconductor fab which matches your highest safety standards. Our team of experts around the globe looks forward to assisting you as a trusted partner with decades of experience.

Excellent Advice: from planning to commissioning and training

Our global service and support network is available to you worldwide, covering every aspect from planning to commissioning – comprehensive support and exceptional service guaranteed. This is complemented by global training opportunities for the purpose of further enhancing operational safety at your sites.

Please feel free to get in touch with your regional expert to assess the potential of SIMONA® SEMICON solutions at your semiconductor fab.

semicon@simona-group.com